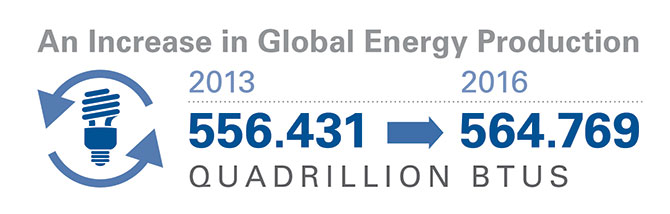

Energy is an extremely valuable asset, as we all know. According to the International Energy Statistics,

global energy production has increased from 556.431 quadrillion BTUs in 2013 to 564.769 quadrillion BTUs in 2016. While there are a vast amount of factors that play into this, one that I tend to home in on is water resource recovery facilities (WRRF).

Did you know that 50-70% of all energy consumed at WRRFs is a result of aeration?

Let’s take a look at aeration energy. Aeration is incorporation of oxygen into the wastewater to promote the biodegradation of carbon and ammonia. Biodegration of one pound of biochemical oxygen demand (BOD) requires one pound of oxygen, while biodegradation

of one pound of ammonia (nitrification) requires 4.6 pounds of oxygen. Denitrification—a process in which microorganisms use nitrate in lieu of oxygen—provides back 2.86 pounds of oxygen per pound of nitrate nitrogen reduced. To put this

into perspective, one cubic foot of air contains only 0.017 pounds of oxygen and it takes 900 cubic feet of air to biodegrade one pound of ammonia (assuming a 30% oxygen transfer efficiency).

Looking at Real-World Examples

I recently gave a presentation to the Rocky Mountain chapter of the Water Environment Federation in Colorado Springs. The presentation focused on various methods for reducing aeration energy at WRRFs and the

pros and cons of each. I reviewed a few case studies, which included our work at the Louisville Wastewater Treatment Plant (WWTP)

and the City of Durango Santa Rita Water Reclamation Facility (SRWRF).

Louisville Wastewater Treatment Plant

In the case of the Louisville WWTP, we designed the biological nutrient removal treatment process to minimize aeration energy while producing higher quality effluent. Our design included deeper aeration basins to increase oxygen transfer, customized tapered

diffuser layout to minimize interferences and decrease flux to improve oxygen transfer, biological nutrient removal (including denitrification), an ammonia based aeration control system, and high-speed turbo blowers. The new treatment process produced

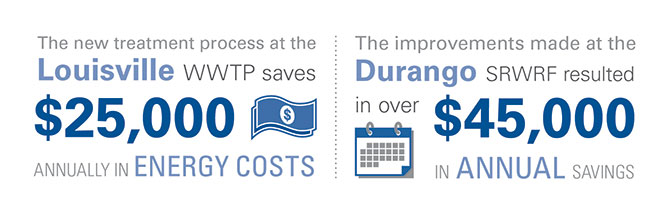

higher effluent quality than the previous extended air process while using less aeration energy in a smaller treatment volume. The new biological nutrient removal treatment process at the Louisville WWTP saves $25,000 annually in energy costs.

City of Durango Santa Rita Water Reclamation Facility

Over at the Durango SRWRF, we designed a biological nutrient removal treatment process to replace its conventional secondary process. Many of the resulting benefits were similar to those at the Louisville plant—we improved effluent quality while

reducing aeration energy. However, the magnitude of the benefit was significantly better due to the increased power costs in Durango. We accomplished this by incorporating primary clarifiers and anaerobic digestion to reduce BOD to the secondary process,

better reactor configuration and design, incorporated an ammonia based aeration control system, tapered diffuser layout with reduced diffuser flux to improve oxygen transfer, and high-speed turbo blowers. These improvements resulted in a reduction

of 50 less aeration horsepower and over $45,000 in annual savings.

Conclusive Impacts

Aeration energy is the largest expenditure in a WRRF budget. Finding ways to reduce aeration energy while maintaining a high level of treatment is desirable to minimize the impact on ratepayers. The easiest

ways to reduce aeration demand are to incorporate denitrification—which can reduce aeration by up to 25%—and primary clarifiers to divert carbon to anaerobic digestion, resulting in up to 30% reduction. Other factors that can reduce aeration

energy include reducing the diffuser flux and installation of energy efficient blower technology. Lowering diffuser flux can improve oxygen transfer by one or two percent which corresponds to an estimated five percent reduction in aeration energy

while upgrading to more energy efficient blowers machines and variable frequency drives can also reduce aeration energy by up to ten percent. Additional aeration energy savings can be realized through a control system specifically designed to minimize

power use while producing the desired quality of effluent.

By considering ways to reduce aeration energy—and there are certainly other ways to do so—WRRFs can play a large role in reducing energy consumption for communities. It’s important that options are weighed carefully, because as is often

the case, there’s not a one-size-fits-all solution.