In the fourth quarter of 2018, manufacturers contributed $2.38 trillion to the U.S. economy, according to NAM, the National Association of Manufacturing. That’s

a lot of domestically produced products, and along with that mass amount of production comes something that many consumers don’t consider—wastewater. Typically, manufacturing facilities produce wastewater that requires treatment before

being discharged to protect the environment and public health.

Processing wastewater that’s generated from manufacturing facilities can be challenging due to high variability and is entirely subject to production operations. While some manufacturers operate the same process consistently, many operate multiple

production lines and batch processes that can be subject to seasonal and product demand. This variability and uncertainty in the wastewater quantity and characteristics can result in treatment system operational issues, regulatory compliance issues,

and uncertainty in how to establish permit limits for the facility and design future treatment infrastructure. Production process modeling with an emphasis on wastewater generation rates and characteristics can provide the clarity required for manufacturing

facilities to make informed decisions regarding wastewater treatment and permitting.

Permitting Support

Some manufacturing facility operators combat variable production schedules and output rates, and consequently struggle to understand if the facility will be able to comply with permit limits under ever-changing production scenarios. Modeling potential

production scenarios and the resulting impacts on wastewater discharges allows manufacturers to evaluate compliance risk, and, if necessary, can serve as the basis to request an increase in permit limits that provide the site with operational flexibility

and the best potential for compliance.

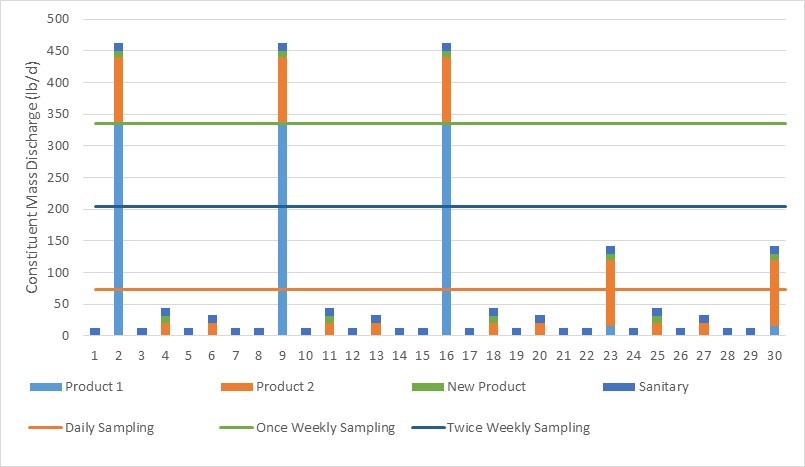

A graphical representation of projected discharge rates over time can help a facility evaluate options for discharge limits.

Communication and Planning

It’s critical that production and wastewater treatment personnel understand the impacts their actions have on one another. Clear communication allows for these groups to anticipate each other’s needs, which will improve operations and can

result in improved environmental compliance. Poor communication can lead to wastewater treatment plant upsets and noncompliance events, both of which contribute to higher operating costs.

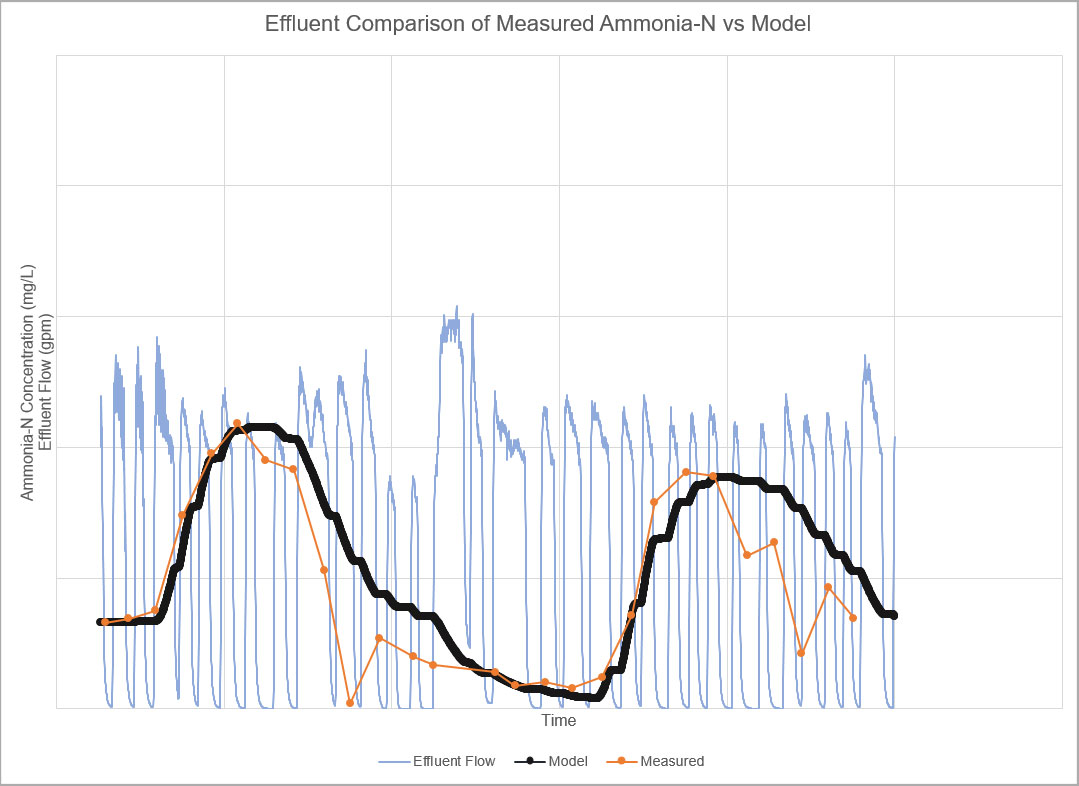

A key element of a collaborative strategy is the development of process models, which predict wastewater impacts under different production scenarios. Predicting wastewater impacts allows operators to make necessary adjustments to successfully

treat wastewater during changing production conditions. Wastewater impact assessments can also be used retroactively to investigate the source of a noncompliance event or upset and better inform the facility operators in order to reduce the risk of

similar events happening in the future. Finally, process models can assist with sizing and design of new or modified wastewater treatment infrastructure.

An effluent discharge model is calibrated to real ammonia data to refine the effectiveness of the model.