New York City is comprised of a 6,800-mile water distribution system that delivers more than 1.2 billion gallons of water to residents, business, and visitors daily. With the replacement of the 114-year-old City Island Bridge, which connects NYC’s

Borough of the Bronx with City Island, came the opportunity to implement a new method of design to replace the failing and non-redundant existing water main connections. Originally laid on the bay floor just south of City Island Bridge, the water

main serves as the sole water supply to City Island.

The team needed to come up with a plan to replace the original main line, since the temporary bridge was constructed directly where the current line lays. We worked with the NYC Department of Design and Construction (NYCDDC) and the NYC Department of

Environmental Protection (NYCDEP) to devise an innovative approach to water main installation by drilling through hard rock underneath the river bed.

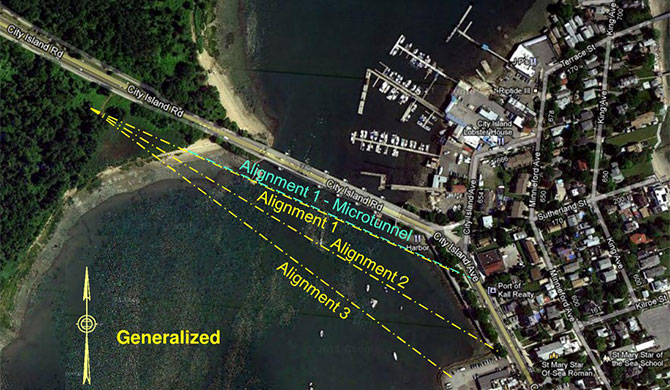

After construction of the bridge was concluded, the temporary line was to be transferred to the new bridge. Instead of that plan, we determined the best course of action was to install two 20-inch diameter, restrained joint ductile iron (RJDI), subaqueous

water mains between Pelham Bay Park, Bronx, and City Island. These new water mains replace the two existing unlined cast-iron water mains and improve the distribution of water in the area.

How to Decide What Trenchless Technique to Use

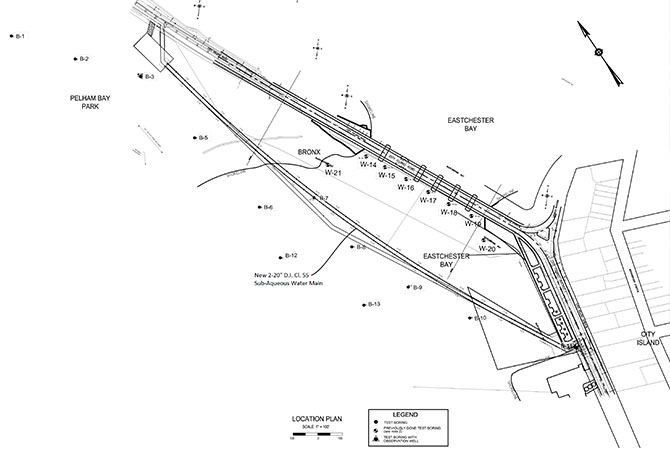

Before we could decide what trenchless technology to use, we needed to understand the geotechnical characteristics of the site. Our findings were summarized in three categories: soils encountered - land test borings, soils encountered - marine test borings,

and bedrock encountered - land and marine test borings.

We developed the boring location plan in relation to the proposed water main alignment. This plan was used to identify the material classifications, strength properties, deformation properties, and groundwater table behavior.

Through these findings, we concluded the best technologies to investigate further were jacking, microtunneling, and horizontal directional drilling (HDD).

Jacking

Jacking is the simplest and most economical method to complete a trenchless waterway crossing. It consists of removing the soil from the heading by hand mining or with an auger. The leading section of the pipe or casing can be fitted with a simple shield

arrangement to maintain the soil plug at the leading head. Unfortunately, jacking is not generally feasible for distances of more than 300 feet.

Microtunneling

Microtunneling is a process where a remote controlled, non-manned entry tunneling boring machine is used to bore a tunnel through the earth or rock. The machine is advanced through the ground by a pipe or casing jacking from jacking shafts. The earth

or rock cuttings are removed and mixed with a slurry that’s pumped to the jacking shaft and then to the surface for disposal.

Horizontal Directional Drilling

HDD requires drilling a small pilot hole and subsequently enlarging the hole to the desired diameter. During the enlarging process, the 20-inch RJDI pipe could be pulled through the hole or a larger casing pipe could be installed prior to the installation

of the RJDI water mains.

The team presented the technology available and costs associated with the trenchless technology to NYCDDC and NYCDEP.

What worked best for the City Island Water Mains?

We decided the HDD method would be the most cost-effective method for this project. Due to geotechnical challenges, distance, size of the pipe, and NYCDEP’s requirement that water mains must be installed in casing pipes, the HDD method was the best

option.

The construction method of HDD played a critical role in successfully executing this project by providing economical, practical, and environmentally responsible ways to install buried pipeline systems.

The lessons we learned from this project will help assist the designers, contractors, and municipalities with their future decision making and continue to improve how we use trenchless technology.

This view is the exit side of the staging area showing the bulkhead and cove area. The team avoided any interference with the bulkhead on the City Island side.