During the Insulated Conductors Committee meeting, industry and technical experts shared information regarding cable design, construction techniques, and specifications. I attended presentations on offshore wind, river crossing with submarine cables, horizontal directional drilling, and upgrades to decades old pipe type infrastructure in many of our nation’s older cities. Across each of these presentations and others, were a direct relationship to the site/civil engineering, permitting, and land-rights based consulting services we provide.

Trending: Transmission Lines for Renewable Energy Sources

Renewable energy sources such as offshore wind are likely to play a role in providing sustainable power for parts of the mid-Atlantic and Northeastern U.S. With legislation and guidelines in place for New Jersey, New York, and Massachusetts, laying a path for such renewables to contribute 3.5GW, 2.4GW, and 3.2GW of power by 2030-35, understanding the policy drivers and constituent technical parts is important.

In the U.S., these newer power sources will be regulated by many agencies at local, state, and federal levels including regional transmission organizations like PJM, the Bureau of Ocean Energy Management (BOEM), and the Bureau of Safety and Environmental Enforcement (BSEE).

Riverine and water body crossings are projected to be an ongoing need as transmission and distribution of renewable power sources and micro grids are developed closer to the end user, and corridors within existing road right-of-way are unavailable or not permitted.

230kV ducts open trench construction.

Trending: The Need for Updated Underground Pipe Type Infrastructure

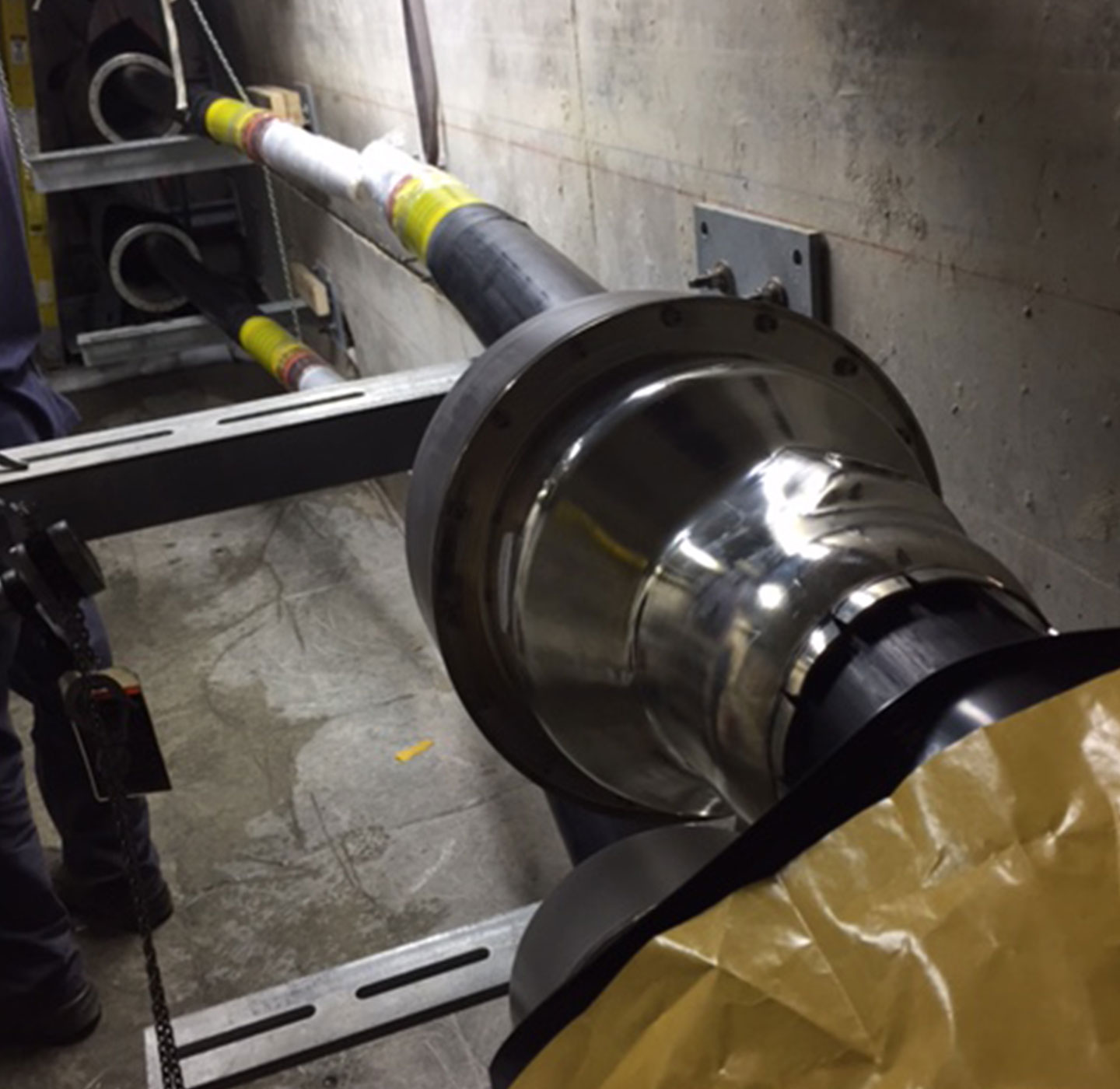

It’s estimated that nearly 3,280 linear miles of underground pipe type cable is installed in the U.S. —primarily in our older, heavily urban centers. Replacing this infrastructure when needed is feasible, albeit costly, but it has risks. There’s only one supplier of replacement cable in the U.S., and new techniques for retrofitting are quickly gaining steam. Retrofitting entails keeping the existing underground steel conduit in place and replacing the “wet” cable with a dry cable. To date, in the U.S., only one utility has installed a live feeder segment for testing using a pipe-type scenario with dry cable, and we were the lead site/civil and design consultant for the project. Time will tell if the new cable technologies and a retrofit model are feasible, but we’re at the forefront in some respects.

138kV cable splicing operation inside vault.

Where We’re Making an Impact

For the past eight years, we’ve been growing capabilities in this specialized market—particularly in the mid-Atlantic region in urban centers where we have mapped, routed, engineered, overseen construction and peer reviewed more than 150 miles of underground distribution and high voltage transmission lines. With these underground transmission lines costing at upwards of $13.5 to $15-million a mile, our firm has had a hand in nearly $2 billion of actual or anticipated project spend.