Tunnel boring machines have evolved tremendously since their mid-1840s inception (nearly two decades before the Civil War). They're now powerful enough to carve through Yucca Mountain and have the endurance to carve close to 100 miles of underground passages. These machines come in all shapes and sizes, the largest measuring nearly 60 feet in diameter and one of the smallest of which became the solution to a temperamental tunneling project in Suffolk, Virginia.

Microtunelling machine exiting at the receiving pit through the seal wall.

With the Precision of a Fine-Tipped Pen

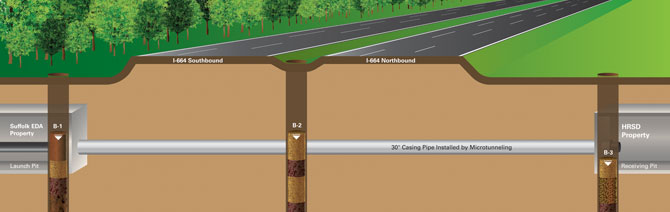

While providing engineering services during a 2,500-foot water main project, we ran across an unique 380-foot-long section that required us to install the pipe 12 feet below a six-lane interstate, seven feet below an unusually high water table, and through extremely unstable geotechnical conditions all without the use of excavation.

Our goal was to install a 30-inch casing pipe 12 feet belowground to house a 16-inch water main that would provide service to a large parcel of land scheduled for development. The area's higher than usual water table, which existed just five feet belowground, meant that geotechnical conditions were unsteady at best. The loose, running sands and clays we would have to drill through had a high risk of settlement, and with a mandate that no excavation be performed within the limited access right-of-way, we had to find a way to counterbalance the water and soil pressures while installing the casing pipe—one that wouldn't damage the six-lane interstate that ran above or interrupt the 60,000 vehicles it carried daily.

After evaluating a number of options, we decided to eliminate many of the risk factors by designing an installation solution revolving around slurry microtunneling. With the precision of a fine-tipped pen, the small laser-guided robotic cutterhead would disturb the least amount of temperamental soil while a qualified technician monitored its progress from above.

The tunneling went off without a hitch.

Click for larger image

Four Millimeters

As the machine made its way under the interstate, slurry had to constantly be pumped to its head in order to match the pressure exerted by the soil and water from above. The cutterhead tore through the clay and sand, allowing the advancement of the 30-inch casing pipe behind the microtunneling machine—a process that continued for five straight days around the clock.

We ended up being off target by four millimeters—a huge success considering the length we had to travel. There haven't been many applications of microtunneling in the Hampton Roads area of Virginia, and it's exciting to be at the forefront of what may be a new trend in local pipeline installation.