According to the American Council for an Energy-Efficient Economy, commercial buildings account for 19 percent of the energy consumed in the U.S. MEP performance design is an integrated approach to minimizing energy usage and maximizing performance in an economically feasible way. Whether dealing with new construction or retrofitting an existing facility, there are innovative approaches to architectural and engineering design choices and building systems, as well as operations and maintenance strategies, that can be used to improve performance.

Designing a Facility from the Ground Up

A brand new building is a blank slate, and really, the only major constraint is a project's final design parameters. Conceptualizing a building's MEP design from the ground up creates more opportunities to improve its energy performance. Recently, we've been providing MEP services for a new 155,000-square-foot office building, with a goal of achieving LEED® Gold certification. We're using numerous architectural and engineering design choices and technological advances to meet this criteria and ultimately save our client money.

Solar carport panels, dedicated outdoor air systems, and solar thermal for domestic hot water are among the building system choices we've made. We've also included a smaller dedicated chiller system for nighttime operations so that the larger plant can be shut down, saving energy during non-peak operating hours as this is a 24/7 facility. This is also the first time I've personally designed a project utilizing heat pipe technology that enables the outdoor air sensible heat to be recycled once the moisture is drawn out via cooling, then it is reheated with the recovered sensible heat from the heat pipe, thus eliminating the need for reheat.

The design team also incorporated various architectural energy features to improve the building's performance. For example, the façade of the building is sheathed to provide an energy-efficient building envelope that improves the overall energy use and operations. Additionally, the team determined the proper orientation on the site to minimize energy usage. Five-foot slatted platforms are incorporated on each floor to shade the building and reduce the energy building load, a portion of the facility's roof is green, and the windows are triple glazed for high efficiency and added security. Currently, it's on track to reduce energy consumption by 41 percent annually—beating the LEED Gold requirement of 30 percent over ASHRAE 90.1 2010 baseline requirements.

Improving Existing Systems

Designing improvements for an existing, occupied building is an entirely different challenge. Projects like these can have many unknowns—are there looming issues in the ceiling or behind a wall that cannot be accessed during our design survey? The design should also limit system down times, determine building engineering personnel tolerances, and establish what they need to maintain a minimum function of the building. On top of all of that, you have to consider the occupants, the entities that own the building, and the stakeholders who have a say in the final design. We must account for these challenges during design for a successful outcome.

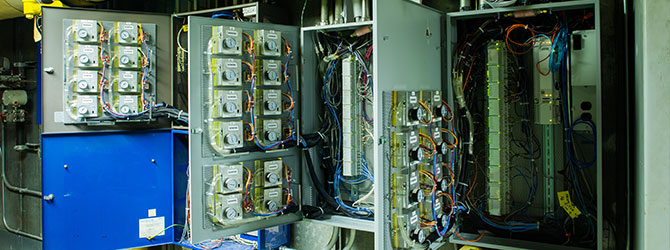

For two multi-story educational facilities in New York, we've been designing upgrades to the aging HVAC infrastructure. Work began with a facility energy assessment (FEA), which evaluated the existing energy program and helped target areas requiring improvement. We addressed major issues like insufficient and inefficient heating and cooling systems and capacity, necessary ventilation upgrades, space temperature variations, user comfort, and energy conservation measures. Our improvements included a new building automation system, low-e window film applications, upgrades to the floor ductwork, VAV boxes, local controls, and a boiler feed water chemical treatment system. We also replaced steam and condensate piping, steam to hot water heat exchanger, perimeter units used for cooling and heating, steam traps, and cooling towers utilized in a redesigned chiller plant. For this project, we couldn't simply take the building offline to complete upgrades or improvements. We were able to bring the building up to code, design and install the equipment in a sub cellar, while minimally affecting occupants through temporary system connections or phased design and construction.

Each project—new construction or existing—has its own set of challenges. Once a design is complete, the building owner has to be able to afford it. Our approach to MEP design ultimately saves money, maximizes performance, minimizes energy usage, and provides a final product that can exceed the expectations of our clients.